Buddy told me that max is 1/8", I thought the u channel was to think but it was scrap. Most likely going to practice on the failed skid since it is 1/8" ready don't think it can be saved.ErikSS wrote:I don't imagine your polarity is wrong. I would focus on wire speed since you're heat is turned all the way up. Slow down the wire. You may consider practicing on thinner steel. That looks like very thick steel for an 80 amp welder. Have you found any specs on what that model claims to be able to weld? I think you may be trying to weld at or beyond the welders specification all while learning how to weld.

My attempt at making a oil pan skid plate Completed sort of

67 posts

• Page 3 of 4 • 1, 2, 3, 4

2008 TB Radflo coil overs, Z71 rear springs, 2" spacer, skyjacker N8030 shocks, LT285/75R16E Goodyear MTR

My Build ----- MY Youtube Channel

My Build ----- MY Youtube Channel

-

TBYODA - Moderator

- Posts: 1759

- Joined: Mon Apr 01, 2013 9:07 pm

- Location: NY, Rochester

- Name: Robert Sengillo

- Vehicle Year: 2008

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Limited Slip

- Rank: Offroad Rated

All of that splatter is from keeping your feed line too long. When using a flux core welder you have to keep your feed line less than a 1/2". Also it looks like you are rushing your welds. Rather than trying to slow down adjust your wire feed speed. I bet you will see some success at a 5-7 speed. Good luck, and don't get discouraged.

-

CNCwell - Member

- Posts: 81

- Joined: Sun Oct 13, 2013 2:46 pm

- Location: KY, Goshen

- Name: Chris

- Vehicle Year: 2005

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

I would strongly recommend to just start laying some beads on a flat piece of sheet metal until you get comfortable with the speed and process, try joining metal after you can lay down a fairly consistent looking weld. It would also probably be a good idea to clean the metal up, on the area you're going to be welding and the area you clamp the ground to. As far as the spatter goes, it's a flux core welder you're gonna get a good bit.

I'd play with the speed of the wire and probably modify how fast I was moving as well, until I got a better weld. I'm guessing it's a smidge of both. Really try to focus on seeing the puddle and moving it along, and practice in a comfortable position. There's gonna be tons of time to weld in uncomfortable positions in the future.

I'd play with the speed of the wire and probably modify how fast I was moving as well, until I got a better weld. I'm guessing it's a smidge of both. Really try to focus on seeing the puddle and moving it along, and practice in a comfortable position. There's gonna be tons of time to weld in uncomfortable positions in the future.

build thread

All things in moderation, including moderation.

Some people never go crazy... what truly horrible lives they must lead

All things in moderation, including moderation.

Some people never go crazy... what truly horrible lives they must lead

-

v7guy - Moderator

- Posts: 3712

- Joined: Wed Mar 09, 2011 10:17 pm

- Location: NY, long island

- Name: Jason

- Vehicle Year: 2004

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

- Rank: Offroad Rated

Today I went and picked up a Clarke Mig180EN 220v mig welder for $150 off a nice fellow that posted it on CL. She needs a little cleaning but I should be all set with some planed projects for the TB, including redoing my skid with 3/16" steel.  Need to pick up a regulator and tank to use gas but for now I will practice with some flux core I got. Also got to run a 220 line to the garage.

Need to pick up a regulator and tank to use gas but for now I will practice with some flux core I got. Also got to run a 220 line to the garage.

2008 TB Radflo coil overs, Z71 rear springs, 2" spacer, skyjacker N8030 shocks, LT285/75R16E Goodyear MTR

My Build ----- MY Youtube Channel

My Build ----- MY Youtube Channel

-

TBYODA - Moderator

- Posts: 1759

- Joined: Mon Apr 01, 2013 9:07 pm

- Location: NY, Rochester

- Name: Robert Sengillo

- Vehicle Year: 2008

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Limited Slip

- Rank: Offroad Rated

Nice

they've always worked for me.

-

HARDTRAILZ - Moderator

- Posts: 6342

- Joined: Sat Sep 12, 2009 1:49 am

- Location: IN, Batesville

- Name: Kyle

- Vehicle Year: 2006

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Extreme Offroader

How close is your dryer to the garage?

You could make a 220v extension cord out of parts from home depot and the appropriate gauge wire and "borrow" the outlet for the dryer. Your wife won't mind, and what the code inspector doesn't know won't hurt him.

You could make a 220v extension cord out of parts from home depot and the appropriate gauge wire and "borrow" the outlet for the dryer. Your wife won't mind, and what the code inspector doesn't know won't hurt him.

Chevy Power!

Long live the Republic

"Violence is not always evil. The judicious use of violence and those willing to use it without hesitation is often all that stands between wolves and sheep."

Build Thread

Long live the Republic

"Violence is not always evil. The judicious use of violence and those willing to use it without hesitation is often all that stands between wolves and sheep."

Build Thread

-

dvanbramer88 - Lifer

- Posts: 2283

- Joined: Tue Jul 05, 2011 3:12 pm

- Location: PA, Bristol

- Name: Dave

- Vehicle Year: 2002

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD

- Rank: Trail Ready

Dave, that's what I did when I rented while in college. Built a whole SCCA rally car running off the dryer plug with an extension cord through the kitchen.

Also, that plug isn't the standard "50A" 220V plug that powers nearly all welders, so if you're going to put in an outlet you might as well go with the right plug.

Mike

Also, that plug isn't the standard "50A" 220V plug that powers nearly all welders, so if you're going to put in an outlet you might as well go with the right plug.

Mike

- bartonmd

- Moderator

- Posts: 4469

- Joined: Wed Sep 09, 2009 9:35 am

- Location: IN, Indianapolis

- Name: Mike

- Vehicle Year: 2007

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ G80

- Rank: Offroad Rated

I remember Mikes ext cord running out my 2nd story window from my dryer plug one weekend for the Lift Meet...

they've always worked for me.

-

HARDTRAILZ - Moderator

- Posts: 6342

- Joined: Sat Sep 12, 2009 1:49 am

- Location: IN, Batesville

- Name: Kyle

- Vehicle Year: 2006

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Extreme Offroader

The plug on the welder I picked up looks like a 6-30P or 30 amp.

2008 TB Radflo coil overs, Z71 rear springs, 2" spacer, skyjacker N8030 shocks, LT285/75R16E Goodyear MTR

My Build ----- MY Youtube Channel

My Build ----- MY Youtube Channel

-

TBYODA - Moderator

- Posts: 1759

- Joined: Mon Apr 01, 2013 9:07 pm

- Location: NY, Rochester

- Name: Robert Sengillo

- Vehicle Year: 2008

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Limited Slip

- Rank: Offroad Rated

What gauge wire do you guy suggest? I was thinking 10 or 8. Is 8 overkill and would using the build type cable be ok for the extension?

2008 TB Radflo coil overs, Z71 rear springs, 2" spacer, skyjacker N8030 shocks, LT285/75R16E Goodyear MTR

My Build ----- MY Youtube Channel

My Build ----- MY Youtube Channel

-

TBYODA - Moderator

- Posts: 1759

- Joined: Mon Apr 01, 2013 9:07 pm

- Location: NY, Rochester

- Name: Robert Sengillo

- Vehicle Year: 2008

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Limited Slip

- Rank: Offroad Rated

Overkill? I didn't know it was possible to overkill welder wiring. I have 2 gauge to my work welder and 8 gauge to my house garage... 110 welder and 220 air compressor.

It's not how fast you go. It's how quick you get there. Lifted TBSS Build

-

ErikSS - Lifer

- Posts: 2044

- Joined: Fri Apr 26, 2013 5:23 pm

- Location: IL, Flossmoor

- Name: Erik

- Vehicle Year: 2008

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Limited Slip

- Rank: Offroad Rated

IIRC, I used 12ga for my 75ft extension cord for my MM211. It only drew 25A, and 12ga is good for 25A at 220V and doesn't have to be de-rated until 100ft.

I had to make a larger one for my MM252, but I don't remember if it's 10-3 or 8-3... I'll check, tonight.

Mike

I had to make a larger one for my MM252, but I don't remember if it's 10-3 or 8-3... I'll check, tonight.

Mike

- bartonmd

- Moderator

- Posts: 4469

- Joined: Wed Sep 09, 2009 9:35 am

- Location: IN, Indianapolis

- Name: Mike

- Vehicle Year: 2007

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ G80

- Rank: Offroad Rated

I ran 8-2 with ground for my welder, that was for a 40 amp breaker.

30 amps is 10-2, and 50 amps is 6-2.

30 amps is 10-2, and 50 amps is 6-2.

-

Trail X - Founder

- Posts: 9925

- Joined: Mon Sep 07, 2009 10:22 pm

- Location: VA, Roanoke

- Name: James Downing

- Vehicle Year: 2005

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Aftermarket Locker

- Rank: Expedition Guide

8ga is 40A or 50A, depending on the temp rating of your wire. With good SJ cord, and the 24.3A rating of the MM211, I was still OK with 12ga SJ cord, especially at the duty cycle. Ratings for wire are at 100% duty cycle for months on end. The MM211 can only do like 10% duty cycle at the 24.3A max, so it never ended up being a problem. It only ever got even warm to the touch a couple times, and I ran my welder up against the over-temperature stop all the time. Even my MM252 only draws 42A, and that's at like a 40% duty cycle, or less.

Mike

Mike

- bartonmd

- Moderator

- Posts: 4469

- Joined: Wed Sep 09, 2009 9:35 am

- Location: IN, Indianapolis

- Name: Mike

- Vehicle Year: 2007

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ G80

- Rank: Offroad Rated

Here is a closer picture of the front.  Doing the math 22.5A x 25% dc = 5.6A....so should be ok with 12 gauge building wire? I think I need to upgrade the breaker it is only a 20A.

Doing the math 22.5A x 25% dc = 5.6A....so should be ok with 12 gauge building wire? I think I need to upgrade the breaker it is only a 20A.

Doing the math 22.5A x 25% dc = 5.6A....so should be ok with 12 gauge building wire? I think I need to upgrade the breaker it is only a 20A.

Doing the math 22.5A x 25% dc = 5.6A....so should be ok with 12 gauge building wire? I think I need to upgrade the breaker it is only a 20A.2008 TB Radflo coil overs, Z71 rear springs, 2" spacer, skyjacker N8030 shocks, LT285/75R16E Goodyear MTR

My Build ----- MY Youtube Channel

My Build ----- MY Youtube Channel

-

TBYODA - Moderator

- Posts: 1759

- Joined: Mon Apr 01, 2013 9:07 pm

- Location: NY, Rochester

- Name: Robert Sengillo

- Vehicle Year: 2008

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Limited Slip

- Rank: Offroad Rated

TBYODA wrote:Here is a closer picture of the front.Doing the math 22.5A x 25% dc = 5.6A....so should be ok with 12 gauge building wire? I think I need to upgrade the breaker it is only a 20A.

Wrong calculation... The 25% duty cycle means that it can only do that rated current for 2.5 minutes out of 10 minutes.

Building wiring, I'd run 10ga. SJ-cord extension cord, I'd run 12ga.

Mike

ETA: My old extension cord for my MM211 was 12ga, and my current one for my MM252 is 10ga.

- bartonmd

- Moderator

- Posts: 4469

- Joined: Wed Sep 09, 2009 9:35 am

- Location: IN, Indianapolis

- Name: Mike

- Vehicle Year: 2007

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ G80

- Rank: Offroad Rated

FWIW, my wire size specs up to this point were for an extension cord made of quality high-temp J cord or SJ cord..

IMO, if you're going to wire your house for something, I'd personally do 8ga THHN in conduit and a 40 or 50A breaker, and make sure it is marked WELDER on the outlet and the breaker. That way, you have the capacity for whatever welder you get in the future.

The reason I say to mark it WELDER and the reason of 8ga with a 50A breaker doesn't jive with JD's 6ga/50A is because there is actually a separate section in the NEC book for welder outlets and wiring. Because of the duty cycle of a non-robotic welder, the wire size can be de-rated some, because of the lack of heat. Again, standard NEC wire gauge per current is rated for 100% duty cycle for months on end.

Mike

IMO, if you're going to wire your house for something, I'd personally do 8ga THHN in conduit and a 40 or 50A breaker, and make sure it is marked WELDER on the outlet and the breaker. That way, you have the capacity for whatever welder you get in the future.

The reason I say to mark it WELDER and the reason of 8ga with a 50A breaker doesn't jive with JD's 6ga/50A is because there is actually a separate section in the NEC book for welder outlets and wiring. Because of the duty cycle of a non-robotic welder, the wire size can be de-rated some, because of the lack of heat. Again, standard NEC wire gauge per current is rated for 100% duty cycle for months on end.

Mike

- bartonmd

- Moderator

- Posts: 4469

- Joined: Wed Sep 09, 2009 9:35 am

- Location: IN, Indianapolis

- Name: Mike

- Vehicle Year: 2007

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ G80

- Rank: Offroad Rated

Yea figure that out after I posted.bartonmd wrote:Wrong calculation... The 25% duty cycle means that it can only do that rated current for 2.5 minutes out of 10 minutes.

2008 TB Radflo coil overs, Z71 rear springs, 2" spacer, skyjacker N8030 shocks, LT285/75R16E Goodyear MTR

My Build ----- MY Youtube Channel

My Build ----- MY Youtube Channel

-

TBYODA - Moderator

- Posts: 1759

- Joined: Mon Apr 01, 2013 9:07 pm

- Location: NY, Rochester

- Name: Robert Sengillo

- Vehicle Year: 2008

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Limited Slip

- Rank: Offroad Rated

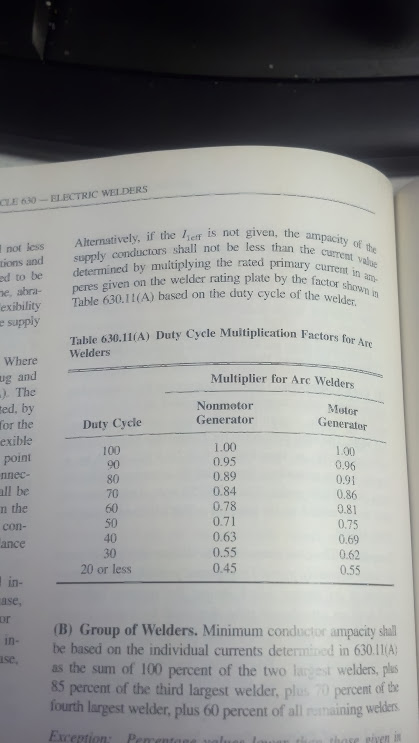

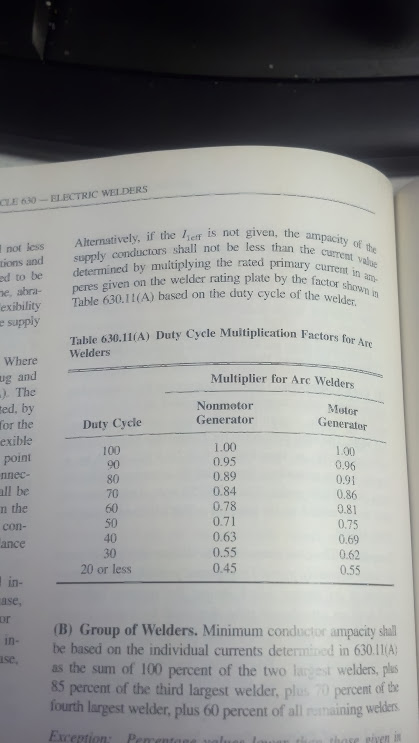

Here's the rating table from the 2011 NEC book:

So, for my MM211, rated at 24.3A max, and rated at 15% duty cycle at 210A

(from the bottom of page 2 of this PDF spec sheet: http://www.millerwelds.com/pdf/spec_sheets/DC12-54.pdf )

means that I have to rate the wire gauge for 24.3A * 0.45, or 10.9A.

So, 14ga (15A) is actually technically OK, but I wouldn't go less than 12ga for voltage drop.

For my MM252, rated at 42A max, rated at 30% duty cycle at 300A

(from the bottom of page 2 on this PDF spec sheet: http://www.millerwelds.com/pdf/spec_sheets/DC12-49.pdf )

means that I have to rate the wire gauge for 42A * 0.55, or 23.1A

However, it says on the back panel that if it pulls down to 200V, it'll pull 48A, so to be safe, 48A * .55 = 26.4A

So, 10ga (30A) is OK for this welder, but I'd prefer 8ga for less voltage drop.

Now, those calculations don't mean there won't be any voltage drop, but they mean that the wire won't melt in the wall or conduit. Having said that, my MM211 didn't noticeably change output between plugged directly into the wall and at the end of a 75' 12ga 3-conductor J-cord. My MM252 doesn't change in any notable way between plugged right into the wall and plugged into the 10ga, 75' 3-conductor J-cord.

Mike

So, for my MM211, rated at 24.3A max, and rated at 15% duty cycle at 210A

(from the bottom of page 2 of this PDF spec sheet: http://www.millerwelds.com/pdf/spec_sheets/DC12-54.pdf )

means that I have to rate the wire gauge for 24.3A * 0.45, or 10.9A.

So, 14ga (15A) is actually technically OK, but I wouldn't go less than 12ga for voltage drop.

For my MM252, rated at 42A max, rated at 30% duty cycle at 300A

(from the bottom of page 2 on this PDF spec sheet: http://www.millerwelds.com/pdf/spec_sheets/DC12-49.pdf )

means that I have to rate the wire gauge for 42A * 0.55, or 23.1A

However, it says on the back panel that if it pulls down to 200V, it'll pull 48A, so to be safe, 48A * .55 = 26.4A

So, 10ga (30A) is OK for this welder, but I'd prefer 8ga for less voltage drop.

Now, those calculations don't mean there won't be any voltage drop, but they mean that the wire won't melt in the wall or conduit. Having said that, my MM211 didn't noticeably change output between plugged directly into the wall and at the end of a 75' 12ga 3-conductor J-cord. My MM252 doesn't change in any notable way between plugged right into the wall and plugged into the 10ga, 75' 3-conductor J-cord.

Mike

- bartonmd

- Moderator

- Posts: 4469

- Joined: Wed Sep 09, 2009 9:35 am

- Location: IN, Indianapolis

- Name: Mike

- Vehicle Year: 2007

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ G80

- Rank: Offroad Rated

Thanks everyone for all the great input here on the skid plate. I had every intention of completing this build remaking from 3/16". However a opportunity fell in my lap in the form of completed skid from fellow member that I could not pass up.

Last edited by TBYODA on Mon Apr 07, 2014 10:40 pm, edited 1 time in total.

2008 TB Radflo coil overs, Z71 rear springs, 2" spacer, skyjacker N8030 shocks, LT285/75R16E Goodyear MTR

My Build ----- MY Youtube Channel

My Build ----- MY Youtube Channel

-

TBYODA - Moderator

- Posts: 1759

- Joined: Mon Apr 01, 2013 9:07 pm

- Location: NY, Rochester

- Name: Robert Sengillo

- Vehicle Year: 2008

- Vehicle: Chevrolet TrailBlazer

- DriveTrain: 4WD w/ Limited Slip

- Rank: Offroad Rated

67 posts

• Page 3 of 4 • 1, 2, 3, 4