I figured the best option would be to center the gears in the collar. I started with some random washers, two 5/8" and one large 1/4" that add up to about 9mm.

I tacked the gear to the collar at two places at a time, let it cool then a few more locations. I really hate flux core.

Took me a few welds to get the heat right and they look real shitty here because I only welded about 1/4-1/2" at time to let the gears/collar cool.

Did I mention I really hate flux core.

Did I mention I really hate flux core.

Here's the back side

Cleaned up

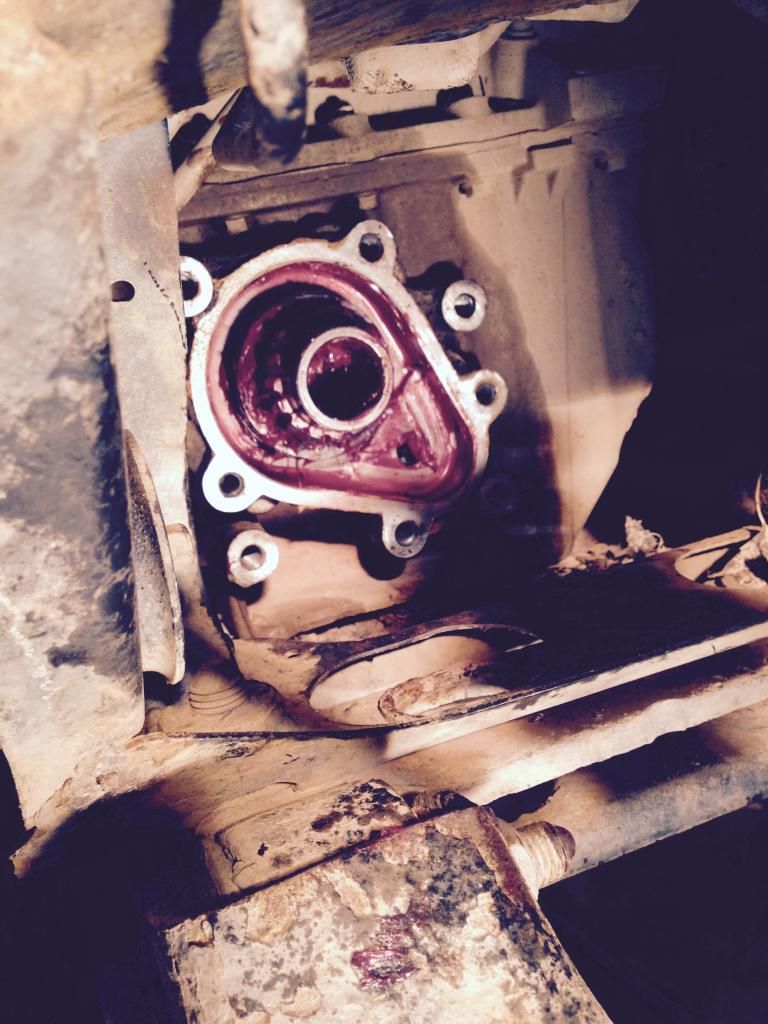

So now that I have my Cheap AWD Sleeve, off to a local GM dealer for parts. I picked up 3 Needle Bearing (2) (GM# 26053326), 1 Outer CV Shaft Seal (1) (GM# 12479302) and 1 Inner Shaft Seal (8) (GM# 15801507) Thanks James for the disconnect write up.

Before I got the bearings, I had some concerns with my globed welds, that I would need the room on the gear for the bearing. My concerns were justified, as the bearing would not spin free without hitting my globed welds. Note to others that try this mod make sure your welds flush to the inner gear (14) and collar as you can.

I figured since the welds were there just to hold the collar in place. I ground down all the high points checking with a bearing as I went along. So far so good now for the install

Since I had my first disconnect repair by fire err freezing cold

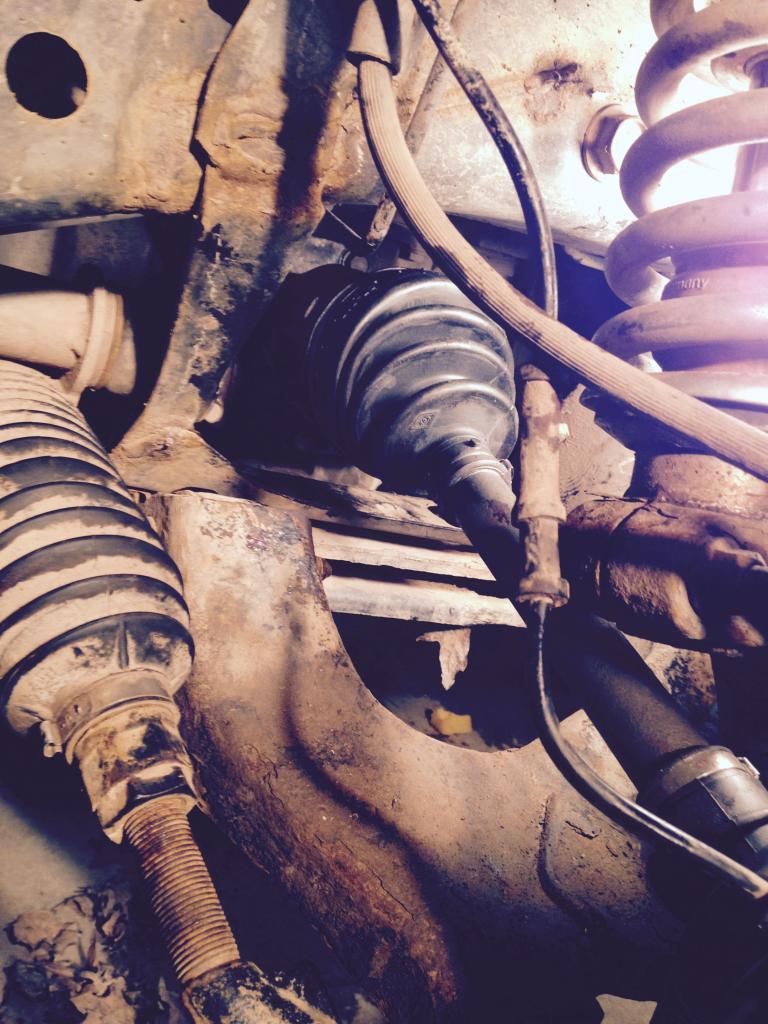

(thanks again guys for all the help) in my buddies heated garage was a cakewalk. However I could not get the disconnect out in one piece so I pulled the outer cover and CV out together like we did at TECORE 11.

(thanks again guys for all the help) in my buddies heated garage was a cakewalk. However I could not get the disconnect out in one piece so I pulled the outer cover and CV out together like we did at TECORE 11.

No damage to the outer case other than the normal numbs getting worn off.

The outer needle bearing are trashed, looked a little rusty in there or could be some Virginia mud as the outer seal was cracked in one spot.

Quick note this bearing was the one closest to the outer gear. After I cleaned it up it looked fine. I did however install new bearings that I bought anyway, guess I have spare now.

All clean

Since I could not get the inner cover off. My buddy Scott came up with ingenious method to get the new grease in the inner needle bearing. We took a plastic bag and made a grease icing bag. I squirted some grease around the bearing and used one of the old gears to push the new grease in the needle bearing. Removed the gear, cleaned up the old grease and repeated a total of 4 times until only red Mobile 1 came out of the bearing.

Cheap AWD Sleeve installed and lubed up good.

Outer case & CV

The surface on my stock CV did not look to good, so I swapped it out with my spare.

Took a test drive through some hard packed wet snow between 8-12" with no issues. When turning tight I could feel the front bind. I know "feel" not a true test but the truck is acting the same as when the 4WD is working. I hope this helps others and is useful to the site.

No, I did not think to clamp the gears together. That is a good idea for future builds if this proves to be a viable mod. I just set the inner gear in the collar and tacked it on opposite sides, let it cool and then welded it a little at a time letting it cool in between.

No, I did not think to clamp the gears together. That is a good idea for future builds if this proves to be a viable mod. I just set the inner gear in the collar and tacked it on opposite sides, let it cool and then welded it a little at a time letting it cool in between.