I've also spent a lot of time organizing my equipment into rugged (dewalt) carrying cases. I'll make a thread about all my equipment and cases at another time. The drawer comes fully out of the enclosure and is removable. The drawer can probably hold about 200 lbs, but I won't stress it that much. I currently have approx 80 lbs in there.

I couldn't justify losing any storage space, so I retained the use of the under-bed storage by having a flap attached to the drawer enclosure.

Also visible in the below picture is one of the retaining pins. The pins hold the drawer in and also out (in case I park facing downhill). The top of the box also has tie down positions for securing cargo on top.

The forepart of the box has a cavity built in. This could be used as extra storage, but I have some bigger plans (more info to come later!).

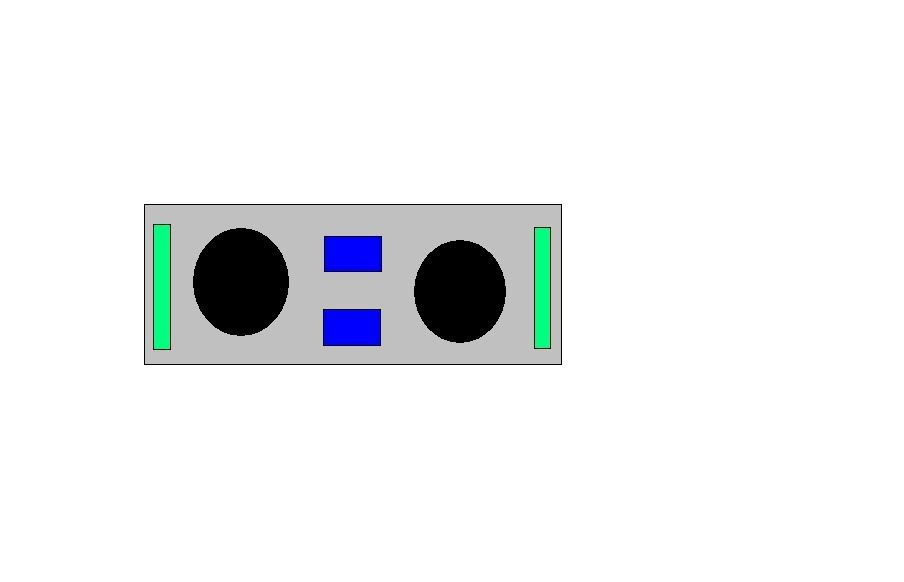

Sadly I don't have many pictures from when it was in its initial construction phase. Lots of test fitting and measuring was involved. I based my measurements off of the modified Dewalt cases that I was using for equipment cases. I knew I wanted to fit those in the drawer; so those were the dimensions that I built around. Since I didn't have good pictures, heres a quick schematic of the internals:

The "Anti-Tip Flaps":

(They wedge under the rear seat hinge flap to prevent the case from tipping forward.)

Mostly assembled:

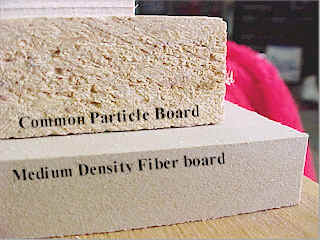

Applying carpet. Carpet glue and heavy duty staples helped the job get done. As you can see, the carpet did not curve around the front lip of the enclosure, but it does in the back and bottom.

Completed drawer without carpet. I tapered the sides for easier access and to make insertion easier. The slides are a little tricky to align.

Test fit with carpet and trim on the drawer. I used an extruded peice of aluminum U to protect the carpet edges. The corner brackets helped hold on the aluminum and protected the corners well.

Close up of the retaining pin. They're made for sliding glass doors as a security device. I especially like the retaining chain so I don't loose the pins.

Completed with hardware installed. i just screwed the handles and tie-downs over the carpet to give it a finished look.

==============================================================

UPDATE, Nov 20, 2009

The prior, unfastened design worked well, but I did notice that the unit slid a couple inches during some of my off road travels. I guess the bumpiness of the trail allows it to walk around a bit.

I wanted to keep it from moving around anymore, so I set about to use the left rear tiedown bolt in the rear of the truck. Well, to summarize, the bolt wouldn't cooperate, I stripped the T45 socket, broke a bolt extractor, and broke the welds on the nut. So I had to cut it off. Below is the bolt, post domination.

So all I had to work with was a hole in the body. With a visit to the hardware store, I found what I needed, a collapsable rubber nut insert. This would be screwed to the main drawer housing, and inserted into the hole in the floor.

Below shows how it mounts to the base of the drawer system. The right picture shows how the rubber part collapses to capture the body sheet metal.

Pictures of the installed parts. The screw head is very low profile (there was not much clearance between the drawer and the drawer housing)... sticks up maybe 1/16" from the wood base.

Would I have rather used the body nut?... Yes. But this is a fine alternative, and doesn't require welding a new nut in place.